深絞り部品カスタム工場精密スタンピング溶接ステンレス鋼アルミニウム溶接部品

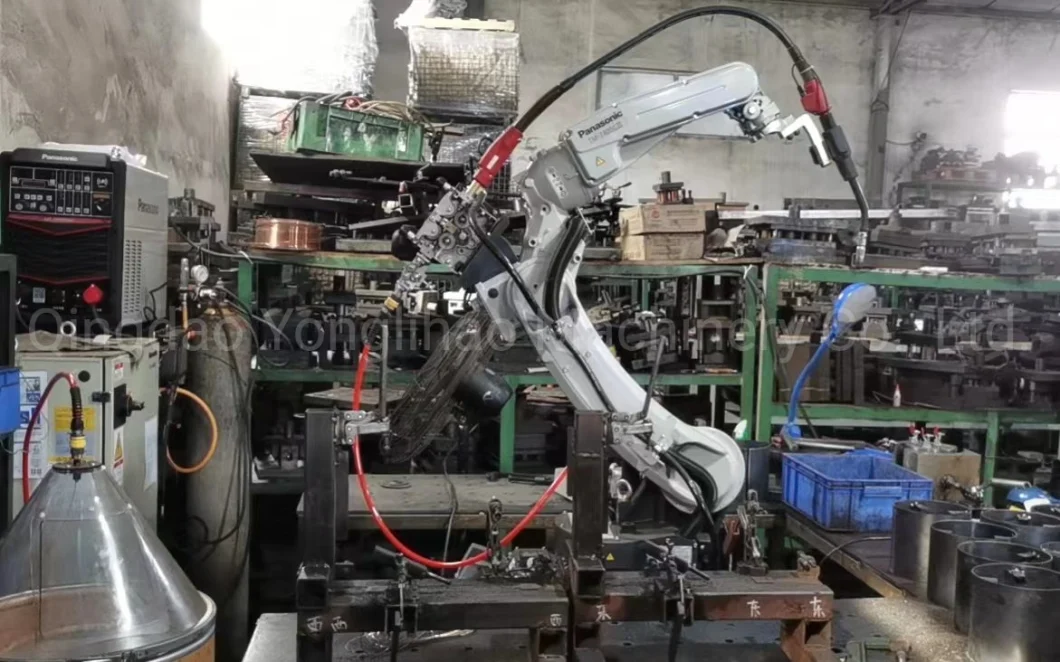

深絞り部品 カスタム工場精密スタンピング溶接 ステンレス鋼アルミニウム溶接部品 製品ディスプレイ溶接 利点: 1. アルゴンタングステンアーク溶接:1) アルゴンは効果的に空気を隔離できます。

基本情報

| プロセス | 成形工程 |

| 業界 | 金属プレス部品 |

| 公差 | 0.1mm |

| カスタマイズされた | カスタマイズされた |

| リードタイム | 15-30日 |

| 対象市場 | 世界中 |

| HS | 73269019 |

| 許容範囲 | ISO2768-F |

| 表面処理 | 塗装/粉体塗装/サンドブラスト/アルマイト |

| 輸送パッケージ | 合板 |

| 起源 | 青島 |

| HSコード | 7326909000 |

| 生産能力 | 500トン |

製品説明

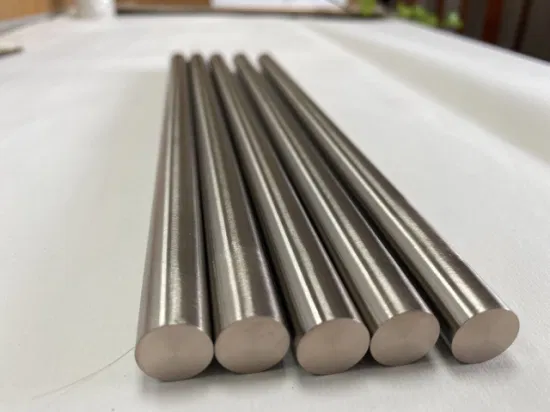

深絞り部品カスタム工場精密スタンピング溶接ステンレス鋼アルミニウム溶接部品| 製品の材質 | Q235/ Q345/ C10/ C20/ C45/ 16Mn等 AL6061/ AL6063/ AL5754/ AL5052等 SUS201/ SUS303/ SUS304/ SUS316/ SUS316L等 H57/ H58/ H59/ H62等 |

| 正確さ | 0.1mm |

| 容量 | 部品:100万/月 |

| 設計ソフトウェア | 3D:PROE/UG/SOLIDWORKS 2D:AutoCAD/PDF/JPEG |

| 表面処理 | 粉体塗装/溶融亜鉛メッキ/塗装/研磨/ブラッシング/クロームメッキ/ニッケルメッキ等 |

| 試験装置 | 硬度計/化学分析/デジタル測定プロジェクター等 |

| 厚さ | 0.1-20mmまたはその他の特殊品も利用可能 |

| リードタイム | 製品に応じて15〜50日 |

| 標準 | ANSI/API/BS/DIN/JIS/GBなど |

| 装置 |

|

| プロダクションのカバー | 軽量製品/建設産業用製品/バルブ製品/自動車部品/自動車部品/設備部品/家具製品など |

製品の展示

溶接の利点:

> Receiving inspection to raw materialAll materials must be provided with suppliers' certificates, and have to pass the receiving inspection before starting production. Occasionally, material samples will be sent to independent lab for specific test to meet customers' demands. All materials have to be tagged and classified, so the original source could be traced at any time during production processes.>> Producing inspectionEvery phase of production processes will be monitored by producing inspection. The first product shall accept test in every phase of production process. Only it completes the test and confirmed by quality control manager, mass production could be operated. Every producing operator will implement constant tests during production processes, including size-measuring, observing the appearance. >>Final inspectionProducts of Yonglihao only can get out of the warehouses after all files signed and sealed.br br>

Q1:Where can I get product & price information?A1:Send us inquiry e-mail or add us whatsapp, we will contact you as we receive your mail. Q2:How long can i get the sample?A2:Depends on your specific items, within 3-7 days is required generally.Q3:What kinds of information you need for quote?A3:Kindly please provide the product drawing in PDF, and will be better you can provide 3D drawing in STEP or IGS format.Q4: What shall we do if we do not have drawings?A4:Please send your sample to our factory, then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions (Length, Hight, Width), CAD or 3D file will be made for you if placed order.Q5: How can we know the chemical component of your products is according to our request?A5: When we offer samples or batch parts, we will also send you our material list from our material factory, it shows more detailed.Q6: How to guarantee your final size can meet our drawing request?A6: we will make moulds according to your 3D drawing. And we also do sampling when batch production start, to make sure the final dimension can meet your request.Q7: How to make sure the color after painting or powder coating can be correct?A7: We have color card with different color number, such as RAL9016, we will contrast the sample surface and color card, to make sure the final surface effect is correct.Q8: Generally, how do you packing the goods?A8: normally, for inner package: the goods is nude, for outer package: carton + plywood. Q9: If we find the defect products exist in the batch parts, how to do?A9: Yes,your caution is very good, in fact, when batch production, we need do sampling. Before shipment, we also do testing to make sure the quality is ok. If you found several defect product exists, pls take photos and send your quality feedback, we will check and send you qualified products. But pls be assured that our products is qualified, unless caused by the worker's mistake to place.

私たちに送ってください